GIUSEPPE DESIRÒ SRL. / DESIGN AND CONSTRUCTION OF AUTOMATIC ASSEMBLY MACHINES

Giuseppe Desirò Srl designs and manufactures automatic machines to assemble Pilfer-Proof aluminum capsules and similar caps, and plastic components for complex closures used in the food, pharmaceutical, cosmetic and household products industries.

Giuseppe Desirò machines are fully managed by PLC and are equipped with a user-friendly man-machine interface that guides operators during machine use, and assists in troubleshooting any difficulties during production. Every stage of the machine's work cycle is constantly monitored by a control function.

The final product output control includes a series of options, including a last generation inspection and vision systems, in addition to a rejects management system and an automatic statistical sampling system.

The finished product is handled with automatic filling of multiple containers, with options that include both multiple outputs and box handling using conveyor carousels or belts.

Working in close collaboration with its customers, Giuseppe Desirò Srl creates custom machines that fully satisfy customer requirements.

For an evaluation, call us +39 055 368403 or write us an email: info@giuseppedesiro.it

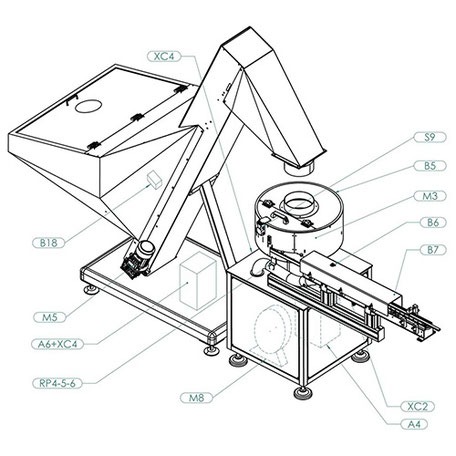

PERIPHERAL SYSTEMS

Giuseppe Desirò Srl. provides many turnkey machine solutions, designing and manufacturing all the peripherals necessary for the perfect functioning of the assembly systems. The integration of auxiliary peripherals into the production systems of the GD automatic machines guarantees minimum downtime and excellent operation of the complete assembly process.

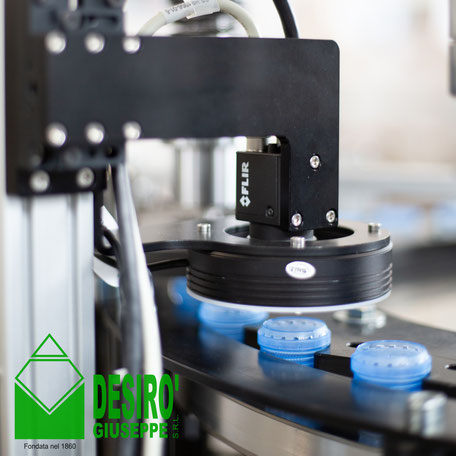

VISION AND INSPECTION SYSTEMS

Every vision and inspection system built into into Giuseppe Desirò Srl Automatic Machines is designed to guaranty that production defects never reach your customers. Giuseppe Desirò Srl mounts only the best quality control vision systems available.

Our partners specialized in vision systems study and develop advanced inspection algorithms to identify size and quality defects, with the aim of reducing the presence of product rejects and defects to zero.