High speed assembly machine

The art of simplifying complex assemblies, for a high speed production output.

Giuseppe Desirò Srl designs and develops automatic machines for the high speed assembly of caps and closures, at up to 1200 pcs per minute.

TYPES OF CLOSURES: Cylindrical caps made up of two or more pieces, by pressure coupling, screwing on and heat deformation.

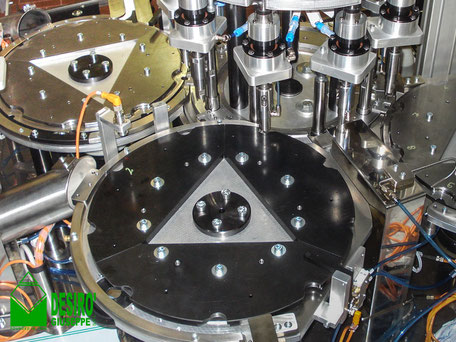

GD5/F3 CONTINUOUS MOTION AUTOMATIC MACHINE TO FOLD THE INTERNAL RING OF THE CAP

The GD5/F3 is an intermittent machine that processes three caps at a time, folding the TE ring of the cap. Furthermore, the machine is equipped with three visions systems for a detailed inspection of the molding of the closure and the integrity of the connection points of the safety rings.

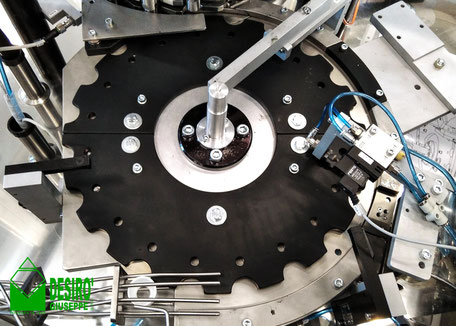

GD33RV - ROTARY ASSEMBLY FOR SCREWING

Rotary assembly machine to screw one capsule onto a second one, with electronically controlled motorized heads, with parameter change through the operator panel. Machine production output is 200 pieces per minute.(Edible Oil, Doy Pack, Spout Cap, etc.)

GD33R3 - CONTINUOUS ASSEMBLER (ROTARY)

Continuous Assemblers Child Proof Chap.

Rotary assembly machines for child-proof caps for pharmaceutical use, with 3 components and production output up to 500/600 pieces per minute.

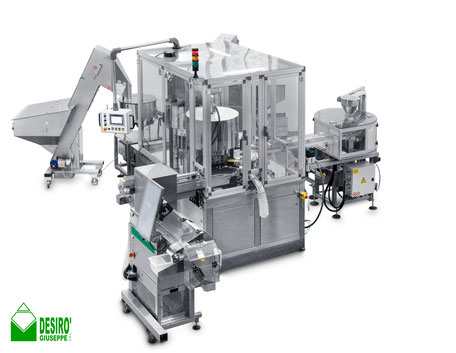

HIGH SPEED ROTARY WELDERS

Rotary welding machines for the hot coupling of aluminum capsules with Flip-Off type plastic discs with a diameter of 13/20/28/32 mm.

Rotary welding machine with 32 heads for production up to 1200 pcs / min.

For all types of welding machines, a wide range of options for controlling the temperature of the heating stations, the color and height of the assembled capsules, vision systems.

They are mainly used when high performance is required (up to 60,000 pcs / hour) with high mechanical efficiency. Furthermore, the component assembly phase is generally more delicate than that in intermittent machines.

GD21WY-3L - HIGH SPEED ROTARY ASSEMBLY MACHINE FOR HOT COUPLING PLASTIC DISK WITH ALUMINUM CAPSULE AND RUBBER LINER INSERTION

The GD21XY3L is a rotary machine for hot coupling aluminum capsules with 20 mm diameter Flip-Off plastic disks. for production up to 320 pcs/min. and the insertion of the pre-cut Rubber Liner. The position of the Rubber Liner in the lower part of the Alu-cap is controlled by a laser sensor which reveals the correct placement. The work cycle is completed with a groove border along the lateral surface of the Alu-cap.

GD21WY - WELDING MACHINE FOR COUPLING THE ALUMINUM CAPSULE WITH THE PLASTIC DISK

Plastic disc welder with aluminum cap.

Rotary assembly machine to couple flip-off caps by heat shrinking the lip of the plastic disks onto an aluminum cap.

Machines with 20/32/40 heads, to produce up to 1200 pieces per minute for formats with diameters ranging from 13 to 32 mm.

For all the types of welding machines, a wide range of options for temperature control on the heating stations, color control, height control on assembled caps, and vision systems.

GD21WY - ROTARY WELDING MACHINE FOR ASSEMBLING AND WELDING THE PLASTIC DISK WITH THE ALUMINUM CAPSULE

Plastic disc welder with aluminum cap.

The GD21WY machine is an automatic machine for assembling and welding the plastic disk with the aluminum capsule. The entire cycle is controlled by the PLC and by the on-board electronics, the operator is continuously informed about the status of the machine from the HMI, the touch screen panel.