PERIPHERAL SYSTEMS

Giuseppe Desirò Srl can offer a wide range of built-in peripheral machines, to complete and increase the efficiency and performance of the assembly machines provided.

Our ongoing research into leading-edge components and on the most innovative electric/electronic solutions allows us to always find the system most suited to your production needs.

PACKING SYSTEM FOR UP TO SIX BOXES

A variety of solutions are available at assembly machine outfeed, to automatically pack multiple boxes in a continuous work cycle, without interrupting operation of the machine, and with special attention on the use of space.

Allows for a better use of available space, and greater safety and ergonomics for operators.

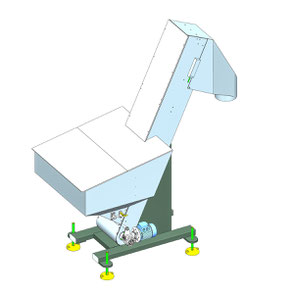

CAP SORTERS

Our series of cap sorters feeds and sorts a wide range of caps at high output rates.