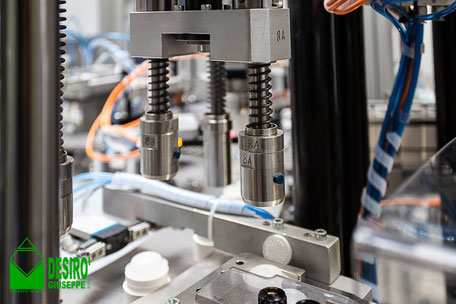

Custom machines

Our engineers develop tailor-made designs, working closely with our customers, to ensure the creation of the ideal production system for every business need. We have what it takes to fully

understand the requirements needed to develop new methods for every specific cap assembly, closing, blanking, folding and sealing function.

Giuseppe Desirò Srl partners with its customers to design and create new machines for very specific needs and requirements. In our many years of machine study and design, we have created machines with devices and/or solutions to complete the assembly stage of components that make up closing systems with ultrasound welding, laser marking and banding machines.

TYPE OF CLOSURES:

Any type of mono-or multiple-piece cap, or even pieces made to the customer's design, with functions other than closing bottles.

GD33 / 12C - SPECIAL MACHINE FOR CLOSING A CAP WITH LID AND INSERTING A SILICONE VALVE

Machine to close caps with a lid and the insert a silicone valve inside it, then cut the disk, in different materials, to be positioned inside the cap itself. Equipped with all the controls required to check the execution of each production stage. Production output of 50/100 pieces per minute, or on request.

GD74 - ASSEMBLY MACHINE UP TO 5 COMPONENTS

Machine to assemble five elements making up an oval stick for creams. Equipped with various linear and rotary electronic peripheral devices and pneumatic components to position pieces with complicated shapes.

Production output of 45 pieces per minute, with multiple checks on the executed phases.

GD84ML - SPECIAL MACHINES DEDICATED TO THE ASSEMBLY OF DROPPERS

This is a new group of automatic machines, dedicated to the assembly of droppers and their unique problems. Hence, there is a wide range of checks on the integrity of the glass rod, its orifice and its brim, both before and after automatic assembly of the dropper.

Assembly of droppers composed of a capsule, a rubber bulb and a glass rod. Production output starting from 50 pcs/min.

GD 77/3/2U - ASSEMBLING MACHINE FOR PRESSURE PASTRY DOSERS

Assembly machine for dispensers / pressure pill dispensers, with interchangeable equipment for format changes. Equipped with ultrasonic welders to couple the two parts making up the container and then insert a dosing slider on the inside. Production output up to 60 pcs/min.